Understanding Foam Conversion: Solutions for Bespoke Acoustics

1. Introduction: What is Foam Conversion?

Foam conversion is a process that transforms raw foam materials into tailored solutions suitable for specific applications across various industries. Whether it’s for sound absorption, insulation, or packaging, foam conversion allows the creation of customized products that meet the diverse needs of sectors like automotive, marine, HVAC, medical, and construction.

At the heart of many acoustic innovations lies the precise art of foam conversion—turning sheets or blocks of foam into bespoke acoustics solutions that tackle real-world noise and vibration issues. With the rise in demand for quieter environments in vehicles, homes, workplaces, and public spaces, foam conversion plays a pivotal role in meeting these modern requirements.

2. The Science Behind Foam Conversion

Foam conversion isn’t just about cutting shapes—it involves a range of techniques that turn a standard material into a high-performing, application-ready product. Common foam types used in the process include:

- Polyurethane Foam: Common in cushions, packaging, and acoustic insulation.

- Polystyrene Foam: Lightweight and insulating, ideal for packaging and construction.

- Polyethylene Foam: Durable and moisture-resistant, often used in padding and transport protection.

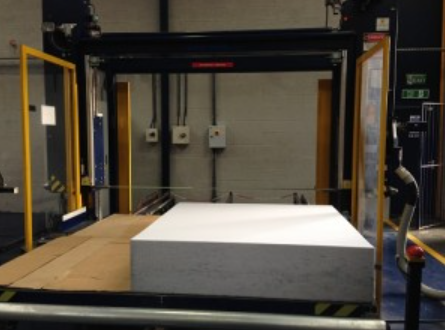

To convert these foams, various specialized machinery and techniques are employed, including:

- CNC Profiling Machines – for intricate custom shapes.

- Die Cut Presses – to create precise forms quickly and efficiently.

- Band Saws & Water Jets – for clean, accurate cuts.

- Slitters & Laminators – for layering and customization.

By combining these processes, manufacturers like Acoustafoam create highly technical acoustic products from seemingly simple foam blocks.

3. Tailored Acoustic Solutions for Every Industry

Automotive & Public Transport

From reducing engine noise to improving passenger comfort, foam conversion is used to design acoustic headliners, armrests, and engine insulation in vehicles. These bespoke acoustics not only improve sound quality inside the cabin but also comply with fire and safety regulations, especially in military and public transport sectors.

Marine & Boats

Noise control is critical on yachts and marine vessels. Acoustic foams tailored through foam conversion can provide both soundproofing and thermal insulation in engine rooms, cabins, and bulkheads. The Class 0 profile foam, in particular, is a preferred choice for marine use due to its fire resistance and sound absorption capabilities.

HVAC & Industrial Acoustics

In factories and HVAC systems, machinery generates disruptive noise levels. Bespoke acoustic enclosures, linings, and panels help control this noise, ensuring safer and more comfortable working environments. Foam conversion allows the design of enclosures that precisely fit the equipment, blocking noise at the source.

Construction Sector

The construction industry frequently utilizes foam solutions to dampen sound within buildings. Whether it’s thermal insulation behind walls or acoustic barriers in ceilings, foam conversion plays a crucial role in energy efficiency and sound control in residential and commercial buildings.

Medical Applications

Medical-grade foam conversion results in cushions, orthopedic supports, and mattress overlays tailored for healthcare settings. These products are designed for hygiene, comfort, and durability, using non-toxic, CFC-free materials.

4. Why Bespoke Acoustics Matter

Standard foam products often fall short when it comes to complex noise problems. That’s where bespoke acoustics shine.

Bespoke acoustic solutions are:

- Precisely Engineered: Custom cut and shaped to fit specific equipment or spaces.

- Functionally Layered: Laminated with barriers like lead foil or polymeric damping sheets for added performance.

- Durable and Safe: Many acoustic foams, like the Class 0 profile, are fire-resistant, chemically inert, and non-toxic.

Whether it’s sound absorption for a construction vehicle’s radiator or insulating an HVAC duct, foam conversion enables creative, high-performance acoustic outcomes tailored to each challenge.

5. The Role of Class 0 Foam in Advanced Applications

Class 0 foam, a standout in acoustic and thermal insulation, is one of the most advanced materials used in foam conversion processes. It’s flame-retardant, flexible, and ideal for environments with high fire risks such as:

- Engine compartments

- Generator canopies

- Heavy vehicles

- Industrial plants

Benefits of Class 0 Foam:

- Nil burn rate and self-extinguishing

- Non-dusting and non-toxic

- Easily moulded to curved or complex shapes

- Available in sheet, profiled, or laminated formats

- Optional self-adhesive backing for easy installation

Combined with foil facing or fabric coverings, it becomes an unbeatable solution for acoustic insulation across sectors.

See also: Small Business Survival Toolkit for Tough Times

6. Benefits of Foam Conversion

Whether you’re in the transport, construction, or manufacturing sector, foam conversion offers several advantages:

1. Customization

Foam can be cut, shaped, moulded, or laminated to suit the specific requirements of a project. No matter how complex the acoustic need, a bespoke solution is possible.

2. Enhanced Performance

Through layering, shaping, and fabrication, converted foam can be engineered for maximum noise reduction, fire resistance, or thermal insulation.

3. Industry Compliance

Converted foam products can be made to meet stringent industry standards, including fire safety (Class 0), durability, and environmental regulations.

4. Cost-Efficiency

Custom foam solutions often reduce the need for additional materials or installations, saving on long-term costs.

5. Eco-Conscious Options

With increased demand for sustainable materials, many foam conversion processes now incorporate recycled or eco-friendly foams to reduce environmental impact.

7. Installation and Maintenance

When installing acoustic foam, strategic placement is key. For effective results:

- Cover at least 20–30% of wall or ceiling surfaces.

- Install at sound reflection points, near machinery, or within enclosures.

- Use high-quality adhesive or mounting brackets for secure attachment.

Maintaining acoustic foam is straightforward. Regular dusting with a soft brush or vacuum keeps the material clean and effective. Avoid moisture and UV exposure to prolong its lifespan.

8. Quality You Can Trust

Companies like Acoustafoam have decades of experience in foam processing and acoustics. With advanced machinery like CNC profilers, die cutters, and laminators, they deliver bespoke acoustic solutions that meet the most demanding requirements.

From Class 0 profiles to composite sound barriers, every product undergoes rigorous quality control to ensure performance, safety, and durability.

9. Conclusion: Your Partner in Foam Conversion & Acoustics

Foam conversion is not just a manufacturing process—it’s a solution-building approach that bridges material science with real-world application. Whether you need to quiet a generator, insulate a boat engine, or improve office acoustics, bespoke acoustic solutions made through foam conversion offer the customization and performance required to meet your needs.

At Acoustafoam, the journey from raw foam to finished product is handled with precision, care, and innovation. Backed by state-of-the-art equipment and decades of expertise, they continue to be a trusted partner in acoustic insulation, noise control, and thermal solutions.

Contact us today to discover how our foam conversion capabilities can elevate your next project.